+86 13816508465

Pump Troubleshooting

Aug. 14, 2023

Electric pumps tend to have problems which often result in breakdowns and expensive repairs with short service life. However, it is possible to prevent these problems if you are aware of the issues and can address them ahead of time.

In this series, we will walk through some of the ways you can troubleshoot these pump problems.

The common pump problems are listed below:

Abnormal Noise

Abnormal Vibration

Abnormal Performance

Other Abnormal

PART-1 Abnormal Noise

The abnormal noise could be caused by below reasons.

1.1 Air-liquid Mixed Discharge

Reason:

There is air inside the pump body, and the air is mixed with water when the pump is running.

Manifestation:

Noise originates from the pump head,

Noise is manifested by poor water flow and fine grunts.

How to Judge:

Shut down the pump and re-exhaust until there is air overflow.

Small Tips: Some pumps donot allow exhausting during operation.

Solution:

Exhaust completely

Check the intake point of the suction pipe

If the intake is a water tank, raise the liquid level of the water tank and penetrate the replenishment pipe below the liquid level.

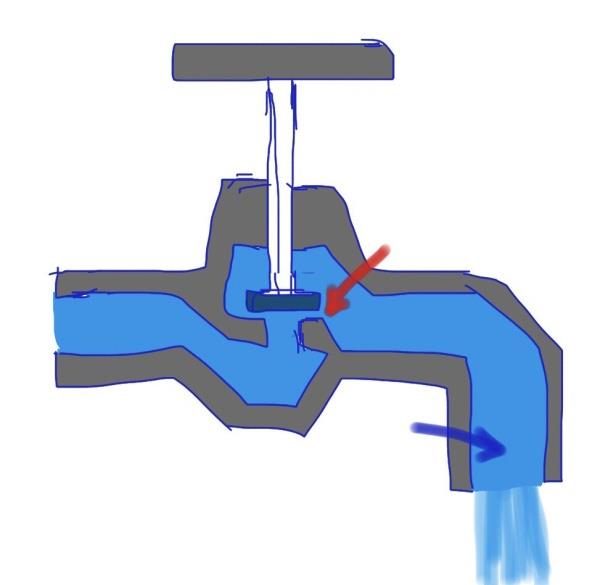

1.2 Pump Cavitation

Reason:

When the pump absorbs water, the water vaporizes due to the pressure drop.

Manifestation:

Noise originates from pump head position

Noise sounds like metal hitting, accompanied by vibrations

How to Judge:

Turn off the outlet valve and let the pump run at 0 flow. The noise will be reduced or eliminated.

Solution:

Check the inlet pressure, the constant pressure value or the water level is reasonable.

Check the liquid temperature and reduce the inlet liquid temperature appropriately.

Reduce the resistance of the inlet pipe, increase the pipe dia. or clean the filter.

Reduce the opening of the outlet valve to avoid overcurrent operation.

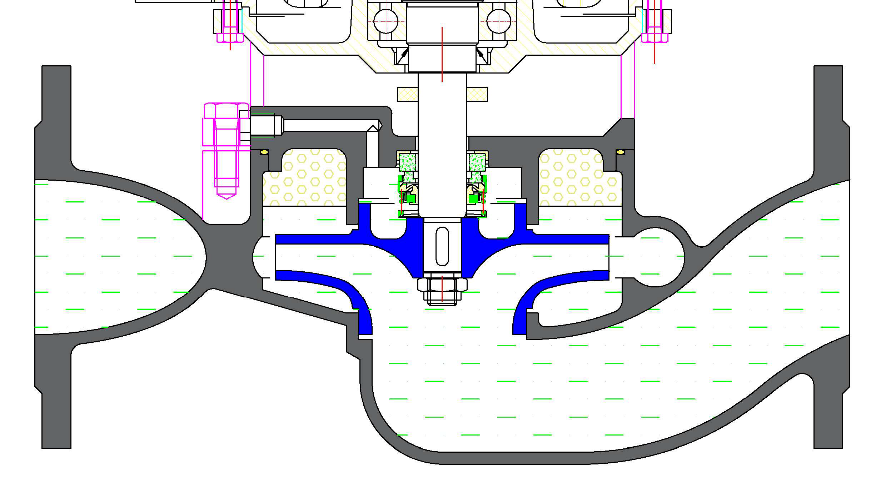

1.3 Pump Body Friction

Reason:

The impeller or pump body is not assembled properly which causes axial or radial contact.

Manifestation:

Noise originates from pump head.

Sharp metal friction noise, which cannot be reduced by constrained outlet valves.

After reducing the pump speed (if possible), the noise frequency drops.

How to Judge:

After stop the pump, stir the impeller manually. Check if there is periodic friction sound at a small angle, and the resistance becomes slightly larger at the same time.

Solution:

Open pump body, check friction points, re-assemble.

1.4 Foreign Objects Entry Inside

Reason:

The pumping liquid contains dirts or debris which enters the gap of the mouth ring and causes friction.

Manifestation:

Noise originates from pump head.

Sharp metal friction noise which cannot be reduced by constrained outlet valves.

After reducing the pump speed (if possible), the noise frequency drops.

How to Judge:

After shutting down, stir the impeller manually. Check if there is periodic friction sound at a large angle, and the resistance becomes more obvious at the same time.

Solution:

Open the pump body, check the position of the foreign objects and the damage degree.

Clean up the foreign objects or replace damaged parts.

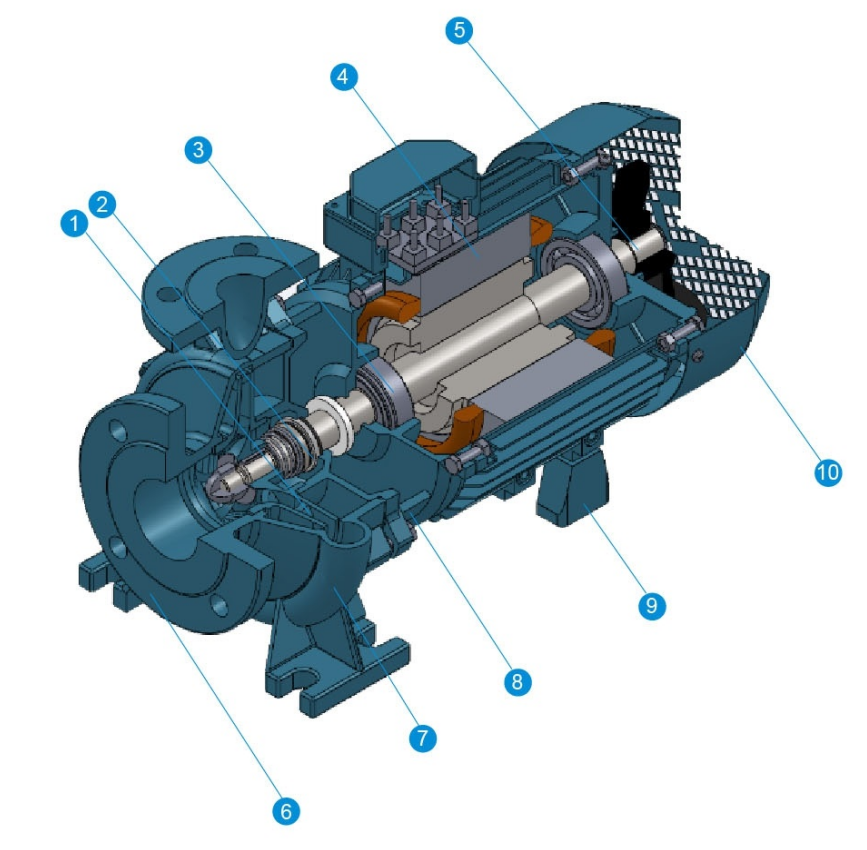

1.5 Bearing Rusted

Reason:

Motor entering water (condensate water), the bearing surface gets oxidized and rusted.

Manifestation:

Noise originates from motor part.

Continuous and coherent sharp metal friction sound.

After reducing the speed (if possible), the noise frequency does not drop significantly.

How to Judge:

After shutting down, manually stir the impeller. The whole circle resistance is large, and it is impossible to stir in severe cases.

Solution:

Disassemble the pump, change the bearings and inspect the rotor parts.

Replace the motor if necessary.

1.6 Bearing Dry Rubbing

Reason:

Motor overheats, bearing’s pre-grease decomposes and loses lubrication.

Manifestation:

Noise originates from motor part.

Continuous and coherent sharp metal friction sound.

After reducing the speed (if possible), the noise frequency does not drop significantly.

How to Judge:

After stopping, stir the pump impeller manually. The whole circle resistance is very large, and it is impossible to crank in severe cases

When dry grinding for a long time, the axial movement of the water pump will increase, and the axial movement can be checked.

Solution:

Disassemble the pump and replace the bearings.

Replace the motor if necessary.

1.7 Fan Friction

Reason:

Fan dislocation caused by external force, friction with motor back cover or fan cover

The fan cover is deformed and rubbed against the fan blades

Manifestation:

Noise originates from motor position

Continuous grinding sound, but not sharp sound

How to Judge:

Remove the fan cover, turn the car manually, and visually check whether the fan rubs against the motor back cover

With the fan cover removed, the water pump starts and the noise is eliminated

Solution:

Use a screwdriver to adjust the fan blades

Just replaced the fan cover

1.8 Excessive Flow Rate

Reason:

The system piping design is wrong, the pipe diameter is too small.

Manifestation:

Noise originates from piping location

The noise is continuous and harsh, accompanied by pipe vibration

How to Judge:

Noise drops rapidly after reducing speed or restricting outlet valve

Solution:

Adjust the valve opening so that the flow rate is within the economic flow rate

Increase the pipe diameter and reduce the internal water flow rate

1.9 Air Vibration (Empty Drum)

Reason:

The foundation on which the pump is installed has low strength. There is a lot of (semi) enclosed air inside, and the air vibrates.

Manifestation:

The noise originates from the pump foundation position

The noise appears as a low continuous noise

How to Judge:

Press and hold the pump or foundation, the noise is significantly reduced

Separate the water pump and the foundation, the noise is significantly reduced

Solution:

Adjust the base structure to solve the enclosed air vibration.

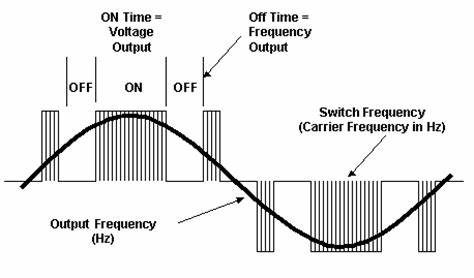

1.10 Electromagnetic Noise (Frequency conversion)

Reason:

The switching frequency (carrier frequency) of the inverter is not compatible with the motor

Manifestation:

Noise originates from motor position

Continuous and high-pitched electromagnetic noise

How to Judge:

Adjust the switching frequency (carrier frequency), the noise returns to normal

Disconnect the frequency converter, the water pump starts directly, and the noise returns to normal.

Solution:

Adjust the switching frequency (carrier frequency)

Address

No.17 XeDa Jimei Ind. Park, Xiqing Economic Development Area, Tianjin, China

Telephone

+86 13816508465

QUICK LINKS